140 engine stumbles when cruising

140 engine stumbles when cruising

I own a 1965 Corsa with a rebuilt 140 4-carb engine; it’s been about 3,500 miles since the rebuild. The engine is essentially stock except for a Clark’s Series2 cam and a Pertronix II ignition with a Flamethrower II coil. I usually add Stabile to every tank of 93 octane gas. My problem is that the engine stumbles once it warms up and I am cruising with a fairly consistent light pedal. When accelerating it will smooth out. When the engine is cold it performs well until it warms up (?). I have replaced the primary carb’s gas filters/stones, checked for vacuum leaks, reset the timing (18 degrees), tightened all the carburetor bolts, and the harmonic balancer looks Okay. The gas tank and sensor are relatively new, having been replaced after the rebuild. Have any of you experienced a similar problem and are there any trouble-shooting suggestions to solving my problem?

Re: 140 engine stumbles when cruising

Usually "stumbling" means surging at constant speed. If it only stumbles when first depressing the throttle pedal that would be the accelerator pumps in the carburetors.RBohl wrote: ↑Tue Oct 31, 2023 12:12 pm I own a 1965 Corsa with a rebuilt 140 4-carb engine; it’s been about 3,500 miles since the rebuild. The engine is essentially stock except for a Clark’s Series2 cam and a Pertronix II ignition with a Flamethrower II coil. I usually add Stabile to every tank of 93 octane gas. My problem is that the engine stumbles once it warms up and I am cruising with a fairly consistent light pedal. When accelerating it will smooth out. When the engine is cold it performs well until it warms up (?). I have replaced the primary carb’s gas filters/stones, checked for vacuum leaks, reset the timing (18 degrees), tightened all the carburetor bolts, and the harmonic balancer looks Okay. The gas tank and sensor are relatively new, having been replaced after the rebuild. Have any of you experienced a similar problem and are there any trouble-shooting suggestions to solving my problem?

I have NO use for the Pertronix Ignitor II and the Flamethrower II coil. Too many issues. I'm not saying that is your problem, but I've had too many problems with these parts. If I install a Pertronix it is the basic Ignitor with a stock coil WITH the Corvair ballast wire in the harness. Rarely do I have an issue with this combination. With Pertronix II parts you have to by-pass the Corvair ballast wire, if you don't you'll have a weak spark.

BTW --- the Pertronix module and plate should have a ground wire between the moving advance plate and fixed plate that bolts in the distributor. If missing you'll have intermittent ignition (for some reason I often find this wire missing).

Since the car is fine when accelerating it does not indicate a lack of fuel or poor ignition. Excess ignition advance at "cruise" can cause surging. A quick way to check is to disconnect AND PLUG the vacuum hose to the distributor advance can. If that fixes you problem you'll have to figure out why your getting too much vacuum advance. If that does NOT fix the surging, then I suspect crude in the carburetor(s). The inlet stone filters only keep out BIG stuff. I always run a quality metal can paper fuel filter between the gas tank and fuel pump.

Let us know what happens. There are other things to look at, but I don't want to type pages of possibilities that can overwhelm.

Re: 140 engine stumbles when cruising

Because it's a "rebuilt" engine, one possibility could be a tight valve adjustment. It warms up, things expand, one or more valves not seating properly. Note: POSSIBILITY. Dennis

- bbodie52

- Corvair of the Month

- Posts: 11951

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 140 engine stumbles when cruising

That Pertronix Flame-Thrower II coil has a 0.6 ohm Primary coil winding resistance and usually pulls a lot of current. It is designed for a full 12 VDC feed.

The Pertronix Ignitor II is engineered to be able to handle ON/OFF switching of a 0.6 ohm Flame-Thrower coil, if the whole ignition system is properly configured. If the ballast resistor wire is still in the circuit, you might try bypassing it. (Tap into the Primary circuit wire on the firewall side of the multiconnector — before the ballast resistor wire).

LEFT CLICK THE IMAGE BELOW TO ENLARGE THE IMAGE FOR BETTER VIEWING. Left-click a second time for maximum enlargement... NOTE: If you wish to measure voltage at the coil positive terminal, you must temporarily ground the negative terminal. (If the negative terminal is NOT grounded, voltage read at the positive terminal will ALWAYS read full battery voltage. The coil must be conducting current to measure any impact of a ballast resistor wire). If the resistor wire has been bypassed or removed, you will measure about 12.5 VDC (full battery voltage) with the negative coil terminal grounded. If the resistor wire is present in the circuit, you may only see about 6-7 VDC. The Flame-Thrower II coil needs full battery voltage to function properly. (SEE THE INSTRUCTION SHEET BELOW.)This diagram gives some examples of where you can tap into the wiring harness on the firewall side of the multiconnector in the engine compartment. Splicing into this connection point connects to full battery voltage BEFORE the ballast resistor wire. This would provide the correct voltage — switched by the ignition switch in the dashboard — to provide full battery voltage to the coil and to the Pertronix Ignitor II module. The Ignitor II module inside the distributor also requires full battery voltage to function properly.

- Attachments

-

- Pertronix Flame-Thrower II Coil Installation Instructions.pdf

- Pertronix Flame-Thrower II Coil Installation Instructions

- (998.5 KiB) Downloaded 10 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 140 engine stumbles when cruising

Suggest u check the distributor bushing for wear [Clarks sells them]. Wear can cause the distributor shaft to wobble and that causes the dwell to vary which will cause a rough engine. If you can find someone with a Distributor Machine you can watch the Dwell dance for you at a steady RPM. Replacing the Bushing is very easy. NOTE: I learned this on my personal 140 '66 vert in 1973 while a GM Training Center Service Instructor.

- bbodie52

- Corvair of the Month

- Posts: 11951

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 140 engine stumbles when cruising

The above suggestion would be more-applicable IF you had a distributor that was still using ignition points. You don't — you have an electronic breakerless ignition module that uses magnetic sensing of the lobes and magnet sleeve on the distributor cam to trigger ignition pulses from the coil to the spark plugs. Dwell is the amount of time the coil Primary winding is energized to build a magnetic field, vs. the period of engine rotation when the coil is switched off by the Pertronix Ignitor II. When coil power is cut by opening the connection of the negative terminal to Ground, the magnetic field produced by the internal Primary coil collapses, which induces a high voltage output from the coil Secondary winding to the distributor cap. That high voltage is routed to the appropriate spark plug via the rotor inside the distributor. (Dwell is established and maintained by the electronic circuitry inside the Pertronix Ignitor II module).unclewill wrote: » Wed Nov 01, 2023 2:25 am

Suggest u check the distributor bushing for wear [Clarks sells them]. Wear can cause the distributor shaft to wobble and that causes the dwell to vary which will cause a rough engine. If you can find someone with a Distributor Machine you can watch the Dwell dance for you at a steady RPM. Replacing the Bushing is very easy. NOTE: I learned this on my personal 140 '66 vert in 1973 while a GM Training Center Service Instructor.

The Ignitor II installation instructions are attached and displayed below. Left-click on each image to enlarge for better viewing, or click a second time for maximum enlargement. The instructions clearly state that the ballast resistor or resistor wire should be bypassed to provide proper voltage to the Ignitor II (and the Flame-Thrower II coil). The final page describes power and ground tests to ensure proper operating environment for the Pertronix components.

- Attachments

-

- Pertronix Ignitor II Instructions.pdf

- Pertronix Ignitor II Instructions

- (170.34 KiB) Downloaded 12 times

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 140 engine stumbles when cruising

There is a misconception the Petronix Ignitor II and Flamethrower II coil uses a lot more current (amperage). This is NOT true. Unfortunately Petronix does not state exactly how they limit amperage, it is most likely a variable dwell scheme that most copied from the GM HEI system.

From the time distributors and ignition coils were common in automobiles (a long time back), engineers have tried to deal with the fact that as an engine speeds up the time to charge/discharge a coil gets SHORTER. If you try to make a coil work better at high RPM it overheats at low RPM. If designed for reliable function at low RPM then at higher RPM the spark gets weaker. What to do? For decades schemes were tried that were either unreliable or EXPENSIVE. Basically the system used in the from the 40's to 70's worked in most cars sold!! Reliable, cost effective for MOST cars. Yes there were systems for high output engines that were for racers that required higher maintenance, but worked better at higher engine RPM.

Thanks to modern micro electronics GM designed the DUAL DWELL HEI system that limited coil amperage at lower RPM, but allowed for a good spark at higher RPM by changing the dwell (time the coil charges) above a certain RPM. This required a low impedance coil pack (usually installed in the distributor cap). History shows this was a reliable and cost effective system for over a decade. GM let the patent expire when they developed advanced computer controlled systems and HEI copies are now abundant, although some are cheap and unreliable.

A WARNING - If you ONLY install the low impedance Flamethrower II coil with regular point or the Petronix Ignitior I module the coil WILL use excessive amperage and overheat the ballast wire and eventually damage either the points or Ignitor I module (technically just the original Ignitor, but most call it the Ignitor I). I seen this incorrect setup a number of times --- more proof the Petronix catalog and technical data does not adequately explain their product for the average person.

From the time distributors and ignition coils were common in automobiles (a long time back), engineers have tried to deal with the fact that as an engine speeds up the time to charge/discharge a coil gets SHORTER. If you try to make a coil work better at high RPM it overheats at low RPM. If designed for reliable function at low RPM then at higher RPM the spark gets weaker. What to do? For decades schemes were tried that were either unreliable or EXPENSIVE. Basically the system used in the from the 40's to 70's worked in most cars sold!! Reliable, cost effective for MOST cars. Yes there were systems for high output engines that were for racers that required higher maintenance, but worked better at higher engine RPM.

Thanks to modern micro electronics GM designed the DUAL DWELL HEI system that limited coil amperage at lower RPM, but allowed for a good spark at higher RPM by changing the dwell (time the coil charges) above a certain RPM. This required a low impedance coil pack (usually installed in the distributor cap). History shows this was a reliable and cost effective system for over a decade. GM let the patent expire when they developed advanced computer controlled systems and HEI copies are now abundant, although some are cheap and unreliable.

A WARNING - If you ONLY install the low impedance Flamethrower II coil with regular point or the Petronix Ignitior I module the coil WILL use excessive amperage and overheat the ballast wire and eventually damage either the points or Ignitor I module (technically just the original Ignitor, but most call it the Ignitor I). I seen this incorrect setup a number of times --- more proof the Petronix catalog and technical data does not adequately explain their product for the average person.

- bbodie52

- Corvair of the Month

- Posts: 11951

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 140 engine stumbles when cruising

I believe that there is a significant increase in amperage based on the reduced resistance in the circuit — which includes removal of the resistance from the ballast resistor wire (1.8 ohms), leaving only the new ignition coil PRIMARY resistance (0.6 ohms) from the Pertronix Flame-Thrower II vs. 1.42 ohms from the original Delco ignition coil plus the 1.8 ohm ballast resistor wire. That additional current through the minimal 0.6 ohm Pertronix coil is great enough to quickly damage ignition points or a Pertronix Ignitor I electronic module. That is why Pertronix specifies that the Flame-Thrower II coil should ONLY be controlled by a Pertronix Ignitor II system, that was engineered to handle the added current through the Flame-Thrower II coil. If the Corvair factory ballast resistor is bypassed, as specified in the Pertronix installation instructions, the total resistance in the new primary circuit is only 0.6 ohms, as opposed to the original 3.22 ohms total (Delco coil plus Corvair ballast resistor wire).

OHM'S LAW

OHM'S LAW

BASED ON NOMINAL 14.5 VDC WITH ALTERNATOR CHARGING OUTPUT & RUNNING ENGINE.

I=V/R (OHM'S LAW: Current = Voltage Divided by Resistance)

I=14.5/3.22 = 4.5 Amps

(GM Primary Circuit with Corvair 1.8Ω Ballast Resistor Wire Plus Delco-Remy Standard 1.42Ω Coil)

I=14.5/0.6 = 24.17 Amps

(GM Primary Circuit without the Corvair Ballast Resistor Wire Plus Pertronix Flame-Thrower II 0.6Ω Coil)

It is true that an ignition coil is not purely a resistive circuit. There is a time factor related to the inductance of a coil, so the DWELL (time that the circuit is ON) impacts the total maximum current flowing through the circuit. So if the time that the circuit is ON (Dwell) is limited, the maximum current flow would be impacted.

In any case, the total amount of current passing through the circuit is significantly greater with the Pertronix Flame-Thrower II coil added to the mix. That is why connecting this 0.6 ohm coil through ignition points or an electronic ciircuit that is not designed to handle a lot of current will tend to quickly burn and damage the points, or can overheat and damage a Pertronix Ignitor I. The ignitor II is made with electronic components that are designed to manage greater amounts of current, so it can handle a coil like the Pertronix Flame-Thrower II, but the Ignitor II is also backwards-compatible with primary circuits that use less current, like a Flame-Thrower 1.5 ohm or 3.0 ohm coil, or a stock Delco 1.42 ohm coil coupled with a ballast resistor wire.

OHM'S LAW

OHM'S LAWBASED ON NOMINAL 14.5 VDC WITH ALTERNATOR CHARGING OUTPUT & RUNNING ENGINE.

I=V/R (OHM'S LAW: Current = Voltage Divided by Resistance)

I=14.5/3.22 = 4.5 Amps

(GM Primary Circuit with Corvair 1.8Ω Ballast Resistor Wire Plus Delco-Remy Standard 1.42Ω Coil)

I=14.5/0.6 = 24.17 Amps

(GM Primary Circuit without the Corvair Ballast Resistor Wire Plus Pertronix Flame-Thrower II 0.6Ω Coil)

It is true that an ignition coil is not purely a resistive circuit. There is a time factor related to the inductance of a coil, so the DWELL (time that the circuit is ON) impacts the total maximum current flowing through the circuit. So if the time that the circuit is ON (Dwell) is limited, the maximum current flow would be impacted.

In any case, the total amount of current passing through the circuit is significantly greater with the Pertronix Flame-Thrower II coil added to the mix. That is why connecting this 0.6 ohm coil through ignition points or an electronic ciircuit that is not designed to handle a lot of current will tend to quickly burn and damage the points, or can overheat and damage a Pertronix Ignitor I. The ignitor II is made with electronic components that are designed to manage greater amounts of current, so it can handle a coil like the Pertronix Flame-Thrower II, but the Ignitor II is also backwards-compatible with primary circuits that use less current, like a Flame-Thrower 1.5 ohm or 3.0 ohm coil, or a stock Delco 1.42 ohm coil coupled with a ballast resistor wire.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 140 engine stumbles when cruising

Your math is correct Brad except you didn't factor in inductance of the coil and the charge time curve.

Impedance provides a much higher resistance until the coil forms a maximum magnetic field. Once the coil magnetic field reaches maximum then only basic resistance applies and THEN the amperage is more!!! The trick is to only charge the coil long enough to form the maximum magnetic field before the coil "-" terminal to ground goes open and THEN the coil magnetic field collapses sending a high voltage pulse to the spark plug.

At lower RPM a shorter dwell reduces the time that amperage flows to the low impedance coil vs. the basic 60's ignition dwell. Some alternatives to limiting the dwell time use circuits that actually sense amperage and limit it. Remember a magnetic coil has IMPEDANCE (resistance and inductance). So basic resistance is only PART of the equation. Also components are rated at AVERAGE power dissipation so the charge curve averaged doesn't require components to handle more amperage (dissipate heat) if the time of maximum amperage is short, or you limit amperage when the coil magnetic field is at maximum. BTW Pertronix claims the Ignitor II can be left on without the engine running and will not overheat, it is also the reason the Ignitor II won't trigger properly below about 800RPM (Corvair Six the RPM is lower for an eight cylinder engine - yup it seems the Petronix II is the same electronics for the six or eight cylinder cars).

The GM HEI was basic and only used two different dwell periods. It was good enough at the time and cost effective. As micro processors got faster and less expensive, spark control advanced dramatically. Now EACH spark plug voltage and amperage is monitored and controlled and if parameters for any cylinder are not within what the computer expects an error code is stored. You won't see a warning light for a random cylinder miss, but if it happens a certain number of times within a certain period - on comes the warning light!!!

It takes about six years to get a BSEE masters degree in automotive electrics that the GM ignition guys have. Yes ignition systems are complicated.

Impedance provides a much higher resistance until the coil forms a maximum magnetic field. Once the coil magnetic field reaches maximum then only basic resistance applies and THEN the amperage is more!!! The trick is to only charge the coil long enough to form the maximum magnetic field before the coil "-" terminal to ground goes open and THEN the coil magnetic field collapses sending a high voltage pulse to the spark plug.

At lower RPM a shorter dwell reduces the time that amperage flows to the low impedance coil vs. the basic 60's ignition dwell. Some alternatives to limiting the dwell time use circuits that actually sense amperage and limit it. Remember a magnetic coil has IMPEDANCE (resistance and inductance). So basic resistance is only PART of the equation. Also components are rated at AVERAGE power dissipation so the charge curve averaged doesn't require components to handle more amperage (dissipate heat) if the time of maximum amperage is short, or you limit amperage when the coil magnetic field is at maximum. BTW Pertronix claims the Ignitor II can be left on without the engine running and will not overheat, it is also the reason the Ignitor II won't trigger properly below about 800RPM (Corvair Six the RPM is lower for an eight cylinder engine - yup it seems the Petronix II is the same electronics for the six or eight cylinder cars).

The GM HEI was basic and only used two different dwell periods. It was good enough at the time and cost effective. As micro processors got faster and less expensive, spark control advanced dramatically. Now EACH spark plug voltage and amperage is monitored and controlled and if parameters for any cylinder are not within what the computer expects an error code is stored. You won't see a warning light for a random cylinder miss, but if it happens a certain number of times within a certain period - on comes the warning light!!!

It takes about six years to get a BSEE masters degree in automotive electrics that the GM ignition guys have. Yes ignition systems are complicated.

- Frank DuVal

- Posts: 499

- Joined: Wed Dec 09, 2009 4:58 pm

- bbodie52

- Corvair of the Month

- Posts: 11951

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 140 engine stumbles when cruising

NOTE: Don Lindfors (now retired) was Director of Exhaust R&D at PerTronix · Full-time from Dec 2007 - May 2022 · 14 yrs 6 mos. Prior to that, he was the Owner of Altered Engineering from Jan 2001 - Jan 2008 · 7 yrs 1 mo.

How It Works - Pertronix Ignition Systems

Don Lindfors of Pertronix Performance Products Serves Up an Electrifying Education

Stephen KimWriter Feb 26, 2014

https://www.motortrend.com/how-to/1404- ... n-systems/

Originally known as Per-Lux, PerTronix was founded in 1962 with the bulk of its manufacturing focus on driving lights and fog lights for the big rig truck market. In the early 1970s, a Per-Lux engineer came up with the idea for an electronic ignition system that replaced the points and condenser in distributors. After patenting the product, PerLux started manufacturing the Ignitor, which originally catered to the fork lift and industrial engine markets. The product gained wide acceptance with fleet managers, who came to realize the dramatic improvement in reliability and reduced maintenance cost it offered. Only a few automotive applications were available in those early years, but automotive enthusiasts began using the Ignitor for the superior performance it offered. Utilizing the Ignitor technology, a complete electronic distributor was developed in 1985 and supplied to Wis-Con, an original equipment engine manufacturer. In 1991, through a series of corporation acquisitions and restructuring, the Per-Lux Ignition division was renamed PerTronix, signaling the company's total commitment to the ignition business.

Ignitions in Action

Most people are familiar with the components in an ignition system, such as the distributor, coil, plug wires, plugs, and ignition box. On the other hand, people are far less familiar with how all these parts work together to transfer the electrical charge from the battery into the combustion chambers. "It all starts with the voltage in the battery, which supplies power to the ignition system. When the driver turns the key, voltage is sent to the ignition coils, and as soon as the motor starts to turn over, the points or electronic module in the distributor opens and closes the circuit," Don explains "When they are closed, a current path of around 10 amps is flowing through the primary windings of the coil, creating a magnetic field within it. When the circuit opens, this primary current suddenly stops and the magnetic field collapses. This change in the magnetic field causes a sharp spike in the primary windings amounting to several hundred volts. Since the coil is a basic transformer, a pulse of up to 50,000 volts moves across its secondary windings. The precise amount of voltage is determined by the spark plug's requirement to fire, which can be anywhere from 5,000 volts or slightly more depending on the condition of the spark plug, the gap, and what is happening inside the combustion chamber. This high current is carried from the coil's high tension terminal, through the coil wire, and to the distributor. The distributor cap sends the current to the rotor, which in turn sends it back to the distributor cap sepal plug wire terminals for each cylinder in a timed manner. The spark plug wires then carry the voltage to the spark plug where the current amps the gap, creating a spark inside the combustion chamber. An ignition box is an optional remote unit that can boost the amount of voltage or create multiple sparks for a stronger, more calculated spark event."

Timing Window

Many hot rodders don't think twice about their ignition system as long as it works. However, as engine rpm increases, the ignition system has less time to light the air/fuel mixture. Consequently, the spark must occur earlier in the power stroke in order for it to have sufficient time to ignite the air/fuel mixture properly. "We must remember that when the spark plug fires, there is not an explosion, but rather a controlled burn. If the mixture truly exploded, the pistons and rods would also explode," says Don. "This controlled burn takes a certain amount of time to complete and as rpm increases, the burn process must start earlier. The burning mixture expands, creating the energy needed to force the piston down against the crankshaft to make power. Peak cylinder pressure occurs between 10- to 20-degrees after top dead center (ATDC) depending on the design of the piston, combustion chamber, and camshaft timing. Since the amount of burn time is relatively stable, we can see that the spark must start earlier for the burn to take place in that same window of 10- to 20-degrees ATDC as rpm increases. All ignition systems have various forms of advance mechanisms in them—either mechanical or electronic—to allow the spark to occur earlier based on rpm or engine vacuum."

What's the Point?

Although points-style ignition systems have served the automotive community faithfully for many years, they have numerous shortcomings. The most obvious is that regardless of whether the subject at hand is a performance vehicle or a grocery getter, ignition points wear out. "The points operate mechanically with a rubbing block that rubs on a small cam in the distributor. This rubbing block wears, which changes the timing and the point gap, altering both the performance and the amount of spark available," Don explains. A points system also requires a condenser, which prevents mini-arcing when the points open and close. Without the condenser, this mini arcing would not only wear the points out faster, but it could also cause the primary winding to collapse across the points. This would weaken the spark, so the condenser absorbs the initial shock of the primary winding and delays it just enough for the energy to travel to the secondary windings, creating spark at the spark plugs. In essence, the condenser is a capacitor that wears out from absorbing all this energy millions of times.

Much like the valvetrain in an engine, the mechanical components that comprise a points system are prone to float and bounce. As the points open and close, they rely on a flat spring to keep them in contact with the cam. This keeps them opening and closing at the right time and with relative precision. As rpm increases, however, they reach the limits of the spring, resulting in float and bounce. "Float is where the spring can't keep up, and the points don't close all the way, causing misfires. Bounce is when the spring is over-stressed and the rapid opening and closing cycles causes the points to bounce back open, creating more misfires as the coil is rising and collapsing at the wrong times," says Don. "To combat this, the PerTronix Ignitor system uses a Hall Effect sensor that replaces the troublesome factory breaking points. The sensor is essentially an electronic switch not limited by rpm or mechanical shortcomings. There are no parts to wear out, so in a healthy electrical system, the Ignitor can operate indefinitely. By not having the problems of points arcing and condenser failings, combined with improved control over the breaking of the current to create the collapse of the magnetic field, a stronger spark is the result. A strong spark is the product of the magnetic field collapsing both quickly and powerfully, and that is something that a Hall Effect sensor does much better than a points system."

Ignitor II and III

"PerTronix's original Ignitor system, which has been on the market now for 40-plus years, is a basic Hall Effect sensor that replaces the mechanical switching of points to an electronic switching system. In contrast, the Ignitor II has built-in reverse polarity protection and over-current protection that shuts down the system, preventing component damage if the key is left on without the engine running. Additionally, the Ignitor II units sense the coil current level and uses a powerful micro controller to adjust the dwell through PerTronix's patented Adaptive Dwell technology. The Ignitor III takes the features of the Ignitor II even further with the addition of a multi-spark feature and a digital rev-limiter built into the module. At PerTronix, we call this ignition box performance without the box. Additionally, the Ignitor II has a built-in four-degree spark retard during start up to ease the start-up stress in high-compression engines."

Adaptive Dwell Technology

"The Ignitor II and III both utilize adaptive dwell technology. To understand what is it and how it works, we first need to define dwell and how it can impact performance. Dwell is the time that the points or the electronic module in an ignition system are closed, and the coil is charging. Standard ignition systems have a fixed dwell angle, meaning that the coil is charged for a fixed period of time during the engine cycle. As rpm increases, that dwell angle has less and less time, so the coil gets charged less per spark event, resulting in a weaker spark. At high engine speeds, a weak spark often becomes the limiting factor for performance and even causes misfires.

"Using Adaptive Dwell Technology, the Ignitor II and III sense the time it takes the coil to charge up to peak current. They use this data to schedule the coil turn-on time so that peak current level is reached just prior to spark for maximum energy without heat buildup, increasing coil and module life. This way they can adapt to any coil that they are connected to. When connected to a stock coil, adaptive dwell maximizes ignition system efficiency, but the real advantage comes when it is used in conjunction with a low-resistance PerTronix Flamethrower II or III coil. Low-resistance coils charge up quickly, and would overcharge and burn up at low rpm in a stock system. The adaptive dwell of the Ignitor II and III keeps the charge time in check at low speeds, and the fast charge time of the Flamethrower II and III coils keeps the spark energy high, much further up the rpm range. The result is a system that works efficiently at low rpm and delivers full spark energy at high rpm."

Voltage Multiplication

"In an ignition system, the purpose of the coil is to multiply the 12 volts supplied by the battery into tens of thousands of volts. A coil is a coupled inductor, consisting of two windings around a common magnetic core. An inductor resists changes in current, so when you switch it on it takes a while for the current to start flowing. More importantly, when you switch it off quickly the current keeps flowing for a bit. This creates a temporary charge across the primary coil winding, bringing the voltage up to several hundred volts. Since the primary and secondary windings are magnetically coupled, their voltages are related by the turn ratio between them. The ratio between the two windings is usually around 100-to-1, so the several hundred volts on the primary side become tens of thousands of volts on the secondary side. At some point, the secondary voltage gets high enough to ionize the spark plug gap, and at that point all of the energy stored in the coil dumps across the plug in the form of a spark.

"PerTronix Flamethrower coils are among the highest quality ignition coils you can buy today. We perform an enormous amount of testing to ensure that each coil meets our quality standards. The resistance and inductance values are selected to match our different modules. In PerTronix's published tech data, you will find where we recommend different resistance values depending on the application. Additionally, PerTronix offers E-Core coils that are far more efficient than conventional canister coils for even stronger spark performance."

On the Corvair, it is fairly easy to splice or tap from the wiring harness at a location just before the engine compartment multiconnector (below the voltage regulator location). On the wiring schematic diagram, locate the wire/wire color on the "firewall side" of the multiconnector. Tapping into the wire at that point will provide you with a full 12VDC source (BEFORE THE SPECIAL RESISTOR WIRE) that is switched on and off by the ignition key. Carefully splice into the wire and run a 12-14 gauge wire around the engine compartment perimeter — along side the engine compartment wiring harness — to reach the ignition coil positive (+) terminal. Note that with this full-time connection to a full 12VDC power source, the Corvair factory connection to the starter solenoid (as a part-time engine startup ignition coil voltage boost) is no longer relevant. Remember that if you relocate the coil away from the hot cylinder head mounting position, the oil-filled coil should be mounted securely with a vertical orientation (as recommended by Pertronix).

Can I mount the Flame-Thrower coil sideways or upside down?

Pertronix wrote:Flame-Thrower coils are made with two different internal materials, oil and epoxy. Epoxy filled coils have a cured resin which supports the coil internal winding's and they can be mounted in any direction. Oil filled coils should always mounted upright to prevent a potential leak of critical fluid as the coil heats up and cools down.

I believe the epoxy-filled coils are designed for a high vibration, competition, boating, or off-road world where the solid-support from an epoxy filled coil will help to protect the internal components from physical shock damage. The oil-filled coils likely do a better job of conducting heat away from the internal windings, and are likely a better choice for a street-driven vehicle where long periods of operation and/or high operating temperatures may be encountered.

Last edited by bbodie52 on Thu Nov 16, 2023 10:44 am, edited 2 times in total.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa ConvertibleRe: 140 engine stumbles when cruising

Thanks for the information Brad, but Petronix usesthe vague and non-descriptive term "Adaptive Dwell" which could mean a number of things. Technically the GM HEI is an adaptive dwell system. A lack of details has always been the issue with Pertronix -- you can't get a definite explanation of how things work. Even after the low RPM mis-fire Corvair fiasco with the Pertronix II, Pertronix never did explain why and has never corrected the problem, yet they don't warn Corvair owners the Pertronix II has issues at low RPM, especially the Powerglide cars when in gear.

Nothing wrong with their product IF you know what to use and what to AVOID.

You mentioned worn distributor bushing are NOT a problem with the an electronic module, only a problem with points. Yes the electronic module systems are not affected as much as points are by worn bushing, however excess distributor bushing wear WILL negatively affect the operation of the electronic module!

Nothing wrong with their product IF you know what to use and what to AVOID.

You mentioned worn distributor bushing are NOT a problem with the an electronic module, only a problem with points. Yes the electronic module systems are not affected as much as points are by worn bushing, however excess distributor bushing wear WILL negatively affect the operation of the electronic module!

- bbodie52

- Corvair of the Month

- Posts: 11951

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 140 engine stumbles when cruising

Whenever an owner or "hot rodder" works to improve a classic car, it involves research, referrals, consumer feedback, and a certain amount of trial and error, and risk. I have attempted to do as much online research as I can with these Pertronix offerings. I have done similar work to research the custom ignition systems offered by FAST (Fuel-Air Spark Technology) with regard to the FAST XR700 and XR3000 units adapted to the Corvair, and I have purchased both and had good luck with both. Many different options and aftermarket performance items have been offered and tried on Corvairs for decades now, in ignition, fuel pumps, carburetion and fuel injection systems, and other engine hardware with different degrees of success and failure.

We are all familiar with the good and the bad in GMs original Corvairs. There was continuous redesign and modifications to the Corvairs over the years as offered to the consumer by Chevrolet. The transition between 1960. 1961 and 1962-1966 was often very significant from model year to model year, so even the GM designers and engineers didn't always "get it right" before it ended up on the dealer's showroom floor.

I am not 100% certain about Pertronix engineering and the products they sell. I tried to pass on what my research and personal experience reveals to me about Pertronix offerings and their performance in street-driven Corvairs. So far I have been satisfied with their products (although I wouldn't put the Ignitor II in my Powerglide-based Corvair with Air Conditioning, since I already am aware of the compatibility issues with a slow-idling 110 hp six-cylinder Corvair when coupled with a Pertronix Ignitor II). I have been running the Ignitor I in that car for over three years now, with good results — far better than ignition points!

I will be trying the FAST XR3000 (as opposed to the FAST XR700) in my Corsa, and I am even trying the FAST I91 inductive coil in that setup, because I think it will work well and I wanted to try a non-canister performance coil because nobody else has written anything about the XR3000 or I91 coil in a Corvair, as far as I know.

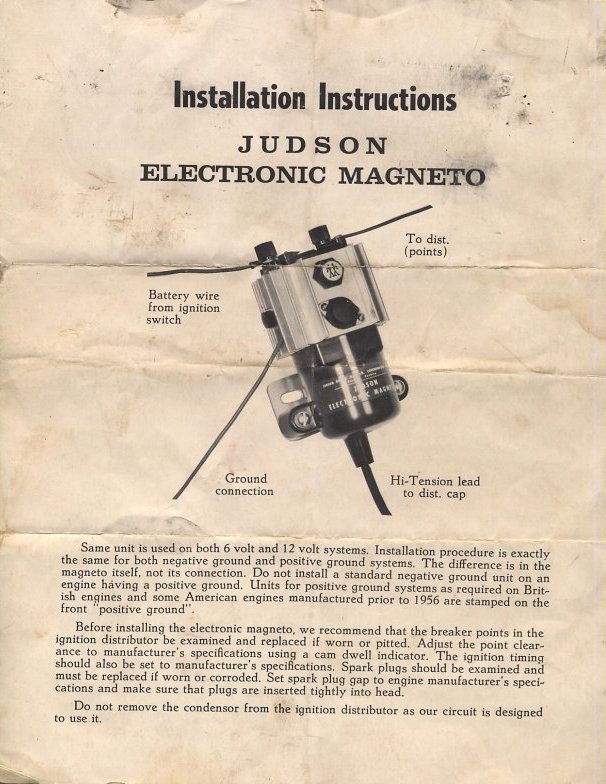

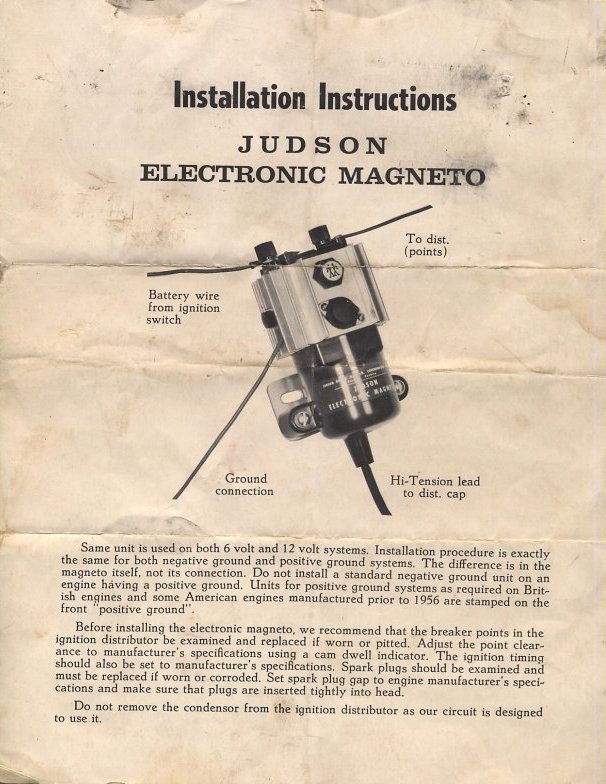

In my youth, at age 18, before I was married, I even experimented with a Judson Electronic Magneto and a Mallory dual-point distributor in my 1965 Corsa back in 1971, along with an IECO center-mounted 450 CFM Holley four barrel and IECO headers. It was all offered in the IECO catalog, and it seemed like a good idea at the time, so I drove my 18 year-old self in my Corvair to the IECO store in Santa Monica and bought all of that Corvair stuff from Raoul F. Balcaen III (Still Alive, Age 87 / Born May 1936), and plugged it into my Corvair.

The headers did not seal very well against the exhaust tube seals on the 140 hp heads. The Holley carburetor I was using was running rich, and the poor exhaust manifold seal permitted air to be drawn into the headers, which would sometimes ignite the fuel in the exhaust and would cause flames to shoot out of the tailpipes. I think I nicknamed them "jet-fire fuel ignitors" (after some J.C. Whitney catalog spark plugs that were on the market back then), and managed to get pulled over and received a few threats from the police in Thousand Oaks — making the Thousand Oaks police angry about my loud, "flame thrower" Corvair exhaust!

Please excuse me for deviating off-course and wandering down memory lane a bit, but this Pertronix debate is getting somewhat old.

If anyone wants to know more about Pertronix items and plugging them into a Corvair...

CUSTOMER SERVICE & TECHNICAL SUPPORT

PERTRONIX LLC

440 E.Arrow Hwy

San Dimas, CA 91773

Phone

909-599-5955

We are all familiar with the good and the bad in GMs original Corvairs. There was continuous redesign and modifications to the Corvairs over the years as offered to the consumer by Chevrolet. The transition between 1960. 1961 and 1962-1966 was often very significant from model year to model year, so even the GM designers and engineers didn't always "get it right" before it ended up on the dealer's showroom floor.

I am not 100% certain about Pertronix engineering and the products they sell. I tried to pass on what my research and personal experience reveals to me about Pertronix offerings and their performance in street-driven Corvairs. So far I have been satisfied with their products (although I wouldn't put the Ignitor II in my Powerglide-based Corvair with Air Conditioning, since I already am aware of the compatibility issues with a slow-idling 110 hp six-cylinder Corvair when coupled with a Pertronix Ignitor II). I have been running the Ignitor I in that car for over three years now, with good results — far better than ignition points!

I will be trying the FAST XR3000 (as opposed to the FAST XR700) in my Corsa, and I am even trying the FAST I91 inductive coil in that setup, because I think it will work well and I wanted to try a non-canister performance coil because nobody else has written anything about the XR3000 or I91 coil in a Corvair, as far as I know.

In my youth, at age 18, before I was married, I even experimented with a Judson Electronic Magneto and a Mallory dual-point distributor in my 1965 Corsa back in 1971, along with an IECO center-mounted 450 CFM Holley four barrel and IECO headers. It was all offered in the IECO catalog, and it seemed like a good idea at the time, so I drove my 18 year-old self in my Corvair to the IECO store in Santa Monica and bought all of that Corvair stuff from Raoul F. Balcaen III (Still Alive, Age 87 / Born May 1936), and plugged it into my Corvair.

The headers did not seal very well against the exhaust tube seals on the 140 hp heads. The Holley carburetor I was using was running rich, and the poor exhaust manifold seal permitted air to be drawn into the headers, which would sometimes ignite the fuel in the exhaust and would cause flames to shoot out of the tailpipes. I think I nicknamed them "jet-fire fuel ignitors" (after some J.C. Whitney catalog spark plugs that were on the market back then), and managed to get pulled over and received a few threats from the police in Thousand Oaks — making the Thousand Oaks police angry about my loud, "flame thrower" Corvair exhaust!

Please excuse me for deviating off-course and wandering down memory lane a bit, but this Pertronix debate is getting somewhat old.

If anyone wants to know more about Pertronix items and plugging them into a Corvair...

CUSTOMER SERVICE & TECHNICAL SUPPORT

PERTRONIX LLC

440 E.Arrow Hwy

San Dimas, CA 91773

Phone

909-599-5955

Last edited by bbodie52 on Fri Nov 03, 2023 11:29 am, edited 2 times in total.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- bbodie52

- Corvair of the Month

- Posts: 11951

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 140 engine stumbles when cruising

Adaptive dwell ignition system

Abstract

An electronic ignition system which is responsive to timing signals generated in timed relationship for providing a substantially constant percent excess dwell time. The timing signals are developed across a sensor coil that is floated between first and second inputs of the system. A capacitor is coupled through a buffer circuit to one of the inputs of the system wherein the timing signal is superimposed onto the voltage developed across the capacitor. A charge and discharge circuit comprising a pair of resistive current sources is utilized to charge and discharge the capacitor during operation. The ratio of the resistive components produces a constant percent excess dwell time that is substantially independent to temperature and process variations.

Inventor: Robert C. Rumbaugh, Robert B. Jarrett

Current Assignee Motorola Solutions Inc

Classifications

F02P3/0453 Opening or closing the primary coil circuit with semiconductor devices

For a lengthy circuit description and summary, click on the following link...

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible- Frank DuVal

- Posts: 499

- Joined: Wed Dec 09, 2009 4:58 pm

Re: 140 engine stumbles when cruising

It is true lots of changes were made across the years of Corvair production But you know what never changed? The basic Kettering system. Oh you might say, the distributor changed from 1961 to 1962. Yes, true, but why? Because GM designed a new distributor for the NEW Chevrolet inline 4 and 6, so they wanted compatibility across the lines. The system worked for 10 years of production. As I have said before, GM went to HEI systems because they were going to have to warranty the emissions of the car for 50,000 miles, and that would mean tune ups were going to be on GM for the first 50,000 miles of vehicle life. So again, it is money that drove the change to electronic ignitions/HEI systems in vehicles."The transition between 1960. 1961 and 1962-1966 was often very significant from model year to model year, so even the GM designers and engineers didn't always "get it right" before it ended up on the dealer's showroom floor."

The reason for this Pertronix discussion was a Corvair was not running right, and it had a Pertronix installed. The only way to test if it is the cause of the problem is to replace it with another unit, or a populated points plate. Same as if it had points installed, substituting with known good parts is the best test. If no good know parts are available one can clean and file the points if needed and reset the gap. And one can test the capacitance of the condenser with modern DMMs, and this will check if it is open or shorted. Of course first up is the Pertronix installed correctly? Again, why there is this discussion. And then those aftermarket coils. They fail waaaayyyyy more often than the GM coils. Again, substituting with known good parts is the best troubleshooting method. And did the owner mistakenly install a Pertronix II? Anywhere on the Pertronix website warning people of the issue running these on low idle six cylinder cars? Lucky we have two Corvair Forums to warn people if they search before buying. Unlucky there is Facebook with the typically wrong answers....

I don't know why the fascination with higher voltage output coils. The voltage in an ignition circuit is limited by the gap of the spark plugs! As soon as the plug fires, the high voltage is shorted, so voltage cannot be higher than what it takes to fire the plug gap. This can be seen on an ignition oscilloscope. The reason for higher voltage output coils is to run wider plug gaps needed to fire leaner mixtures. Hence HEI systems on GM vehicles after 1974. If one follows the Corvair shop manual guide of .030" spark plug gap for the higher horsepower engines the higher voltage output coils are not giving any benefit. The system is still firing at the voltage level of a stock GM coil. Of course if the ignition system can deliver higher voltage, one can increase spark plug gap and see how the engine responds. Experiment. I would caution about trying leaner mixtures, as one can melt a hole in a piston when temperatures of lean burning gets too high. If not going leaner, then not much benefit to wider gaps. As a test, compare the color of the Corvair's spark plugs to the spark plugs of a newer daily driver. The Corvair's most often will be darker from richer operating conditions. Lower operating spark voltage is all that is needed for rich. Now more money can get a fuel injection system and fix that!

Frank DuVal

Fredericksburg, VA

Hey look, blue background!

Fredericksburg, VA

Hey look, blue background!

- bbodie52

- Corvair of the Month

- Posts: 11951

- Joined: Mon Aug 06, 2012 12:33 pm

- Location: Lake Chatuge Hayesville, NC

- Contact:

Re: 140 engine stumbles when cruising

If there had been a question submitted about upgrading the Corvair ignition system BEFORE the hardware had been purchased and installed, I would not have recommended the current Pertronix items (Ignitor II and Flame-Thrower II) BECAUSE they are overkill for the low RPM, low compression ratio street Corvair. The potential issues with low RPM idle on Powerglide Corvairs is another negative. My 1966 Monza Sedan (110 hp Powerglide/Air Conditioning) has been running the Pertronix Ignitor I for several years without any trouble from the Ignitor I. It was already on the car when I bought the Corvair, but so far I have had no problems with it. My main recommendation has always been an upgrade to a relatively simple, stable and reliable FAST XR-700 optical-trigger breakerless system. That unit runs on the reduced voltage from the factory ballast resistor, is easy to install, and works fine with the stock Delco ignition coil. It provides stable and consistent timing and ignition dwell with no wear or variation in dwell and timing while in use (unlike the problematic ignition points and condenser). If Detroit had had access to an inexpensive breakerless electronic ignition system (magnetic pulse or optical trigger) back in the 1950s and 1960s, ignition points and condensers would have disappeared decades before they actually did. This simple upgrade is relatively inexpensive and eliminates frequent tune-ups and timing/dwell adjustments. I wish Electronic Fuel Injection was an inexpensive upgrade for the Corvair. with better airflow and reliability, and often improved gas mileage as well, EFI and electronic ignition would likely bring Corvair reliability toward meeting 21st century expectations.

In any case, the Pertronix II hardware has already been purchased and installed. It can work well on that manual transmission Corvair, so I am just trying to see if the installation was done correctly — adhering to the Pertronix installatiion documentation — so that he can get his money's worth from the Pertronix items.terribleted wrote:...I love my Crane ignitions. I have only ever seen one that had failed. Something I can not say about the Pertronix units where failure is somewhat common from what I have seen.

Corvair guy since 1982. I have personally restored at least 20 Vairs, many of them restored ground up. Full time restoration tech and mechanic. https://www.facebook.com/tedsautorestoration

Last edited by bbodie52 on Sat Nov 04, 2023 2:51 pm, edited 1 time in total.

Brad Bodie

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible

Lake Chatuge, North Carolina

1966 Corvair Corsa Convertible

1966 Corvair Corsa Convertible